Powerhouse

SPRAY FOAM MAGAZINE – The generator is a key piece of equipment on the rig, and that is why the contractor needs to know exactly what they are investing in and where the equipment is coming from. Spray Foam Magazine spoke with Powerhouse Diesel Generators (PDG), a well-respected generator manufacturer, to find out their story and what makes their company and its generators so special.

PDG was born out of the “Great Recession” in the late 2000s. The company’s owners, Scott and Jennifer Tyler were musicians and for the past 20 years, they had been traveling, booking, and playing events throughout the U.S. That all halted, however, after the birth of their first child. Instead, the Tylers started investing in motor coach conversions to supplement income as they no longer wanted to be on the road full time.

Scott had grown up working on cars and trucks in the recycling business. He implemented these skills while working on large vehicles, from dump trucks to school buses, and even created beautiful coaches from converted tour buses. From late 2008 to early 2009, there was a pivotal point when things would shift gears for the Tylers, changing their lives forever. With over $150,000 invested in a coach conversion project, diesel fuel suddenly hit a record high (at the time), and the market for diesel-driven coaches collapsed.

On the verge of losing everything, and in a moment of despair, Scott and Jennifer prayed and were led to take the diesel generator out of that coach, refurbish/repurpose it, and sell it. As fate would have it, that unit sold and they were able to pay the mortgage and buy the groceries. They knew this was their future and PDG was born.

The Tylers launched their new company out of their South Georgia carport. They bought an old used forklift and loaded one unit at a time on freight trucks that would pull into their residential neighborhood. Thankfully they had very supportive neighbors who to this day they are thankful for. If it wasn’t for their understanding, PDG would not have been possible.

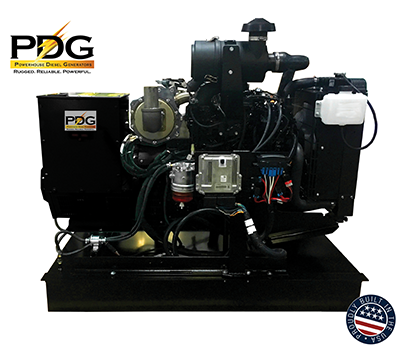

Fast forward 15 years — the company has over 50 employees, 60,000 sq. ft. of manufacturing space, and sends out over 1,000 generators per year ranging from 10kW to over 1000kW. PDG also offers a wide range of products, like standby whole home backup power, mobile trailered on-site power, microgrid / parallel units that work in tandem, and specialized spray foam and concrete rig units that can be tailored and customized to fit the customer’s application.

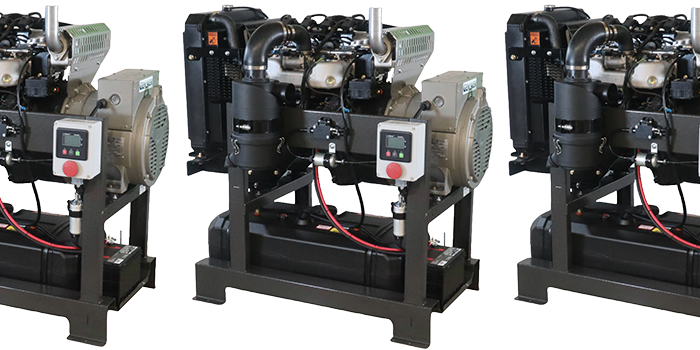

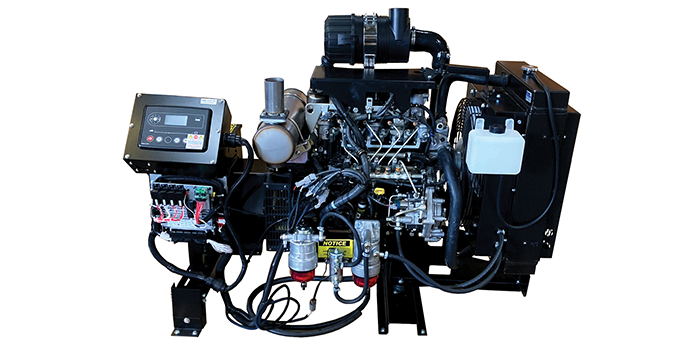

PDG has put in countless hours learning the spray foam industry and developing products specialized for the contractors’ applications. These include compact fuel tanks, low-profile engine cooling systems, and rain-resistant exhaust systems to run the exhaust out of the roof of rigs without letting rain in.

They also have genset control systems paired with ultrasonic flowmeters that can monitor the flow and mixture of the spray foam chemicals. This helps ensure a perfect mix of material used per job (and per hour) so the contractor can record the work the crew is doing.

“The beauty of our products in the spray foam industry is that we know that there is no ‘one-size-fits-all,’ so, we offer a wide array of engines – for example, Yanmar, Kubota, Perkins, John Deere, FPT, Isuzu, Kohler, etc., and generators WEG, Stamford, Marelli, and PDG Industrial, as well as customized cooling packages. If a contractor has a size constraint with their foam rig, we can also tailor a product perfect for you,” clarifies PDG’s Chief Technology Officer, Jonathan Maneer.

The PDG team is 100% USA-based and knowledgeable and experienced in generators. They manufacture their own fuel tanks, enclosures, framework, electrical harnesses, brackets, trailers, etc. They are proud to state that when a customer receives one of their products, everything (excluding the engine block and alternator) from the bottom to the top is made in their Georgia-based facility. This enables them to have complete quality control over the entire build. Even if there is a blemish in some powder coat, they can instantly take it to their powder coat team, sandblast, and recoat to ensure a perfect finish.

PDG’s after-sale support is impressive. Whether the contractor needs some filters, or support with an install, or an issue in the field, the sales team is happy to advise. When contacting PDG, the person on the other end of the phone is an experienced technician who works from the PDG facility, speaks English or Spanish, and is equipped to solve any issue the customer may have. Alongside their generators, they offer over-the-phone or on-site installation and operational training to ensure that their customers are equipped with the skills and resources needed for success, and their maintenance contracts provide their customers with everything they need to keep their unit up and running for the long haul.

Over the next couple of years, PDG plans to expand their facility and property to accommodate the increase in demand. They are currently completing a UL2200 Certification to help enter new markets (The UL2200 certification is a rigorous testing and evaluation process that ensures generators meet strict safety and performance standards) and are planning to more than double their operations to offer more options as well as providing faster lead times.

PDG makes it its mission to provide reliable, on-site electric power wherever it is needed while cultivating the growth and potential of individuals as both professionals and leaders. They also strive to support their customers by extending beyond the point of sale. Yes, PDG sells generators, but they also strive to empower communities and businesses with reliable power and foster lasting relationships built on trust and excellence. From stress to success, this is one company that carries those blessings forward into their quality generators and customer service.

For use by SprayFoamMagazine.com & Spray Foam Magazine

Disqus website name not provided.