THERMOBLOCK ICF WALL SYSTEM

ThermoBlock ICF Wall System

Super-Insulating Next Generation ICF™

WHAT IS THERMOBLOCK®?

- 8 X 8 X 32 INCH POLYURETHANE FOAM BLOCKS INTERLOCK AND FIT TOGETHER TO CREATE A SUPER-INSULATING NEXT GENERATION ICF™

- VERTICAL SEAMS ARE GLUED AND SEALED TO CREATE A STRONG BOND AND AN IMPENETRABLE AIR BARRIER

- SIGNIFICANTLY FASTER INSTALLATION WITH LESS LABOR COMPARED TO CMU AND TRADITIONAL ICF. 3-5 MAN ASSEMBLY TEAMS ARE TYPICAL.

- ALL BLOCKS AND STEEL FRAMING MEMBERS CAN BE MANUFACTURED ON SITE. THIS SIGNIFICANTLY REDUCES SHIPPING AND TRANSPORTATION COSTS, AND ELIMINATES LONG PROCUREMENT LEADS TIMES COMMONLY ASSOCIATED WITH CONSTRUCTION MATERIALS THESE DAYS.

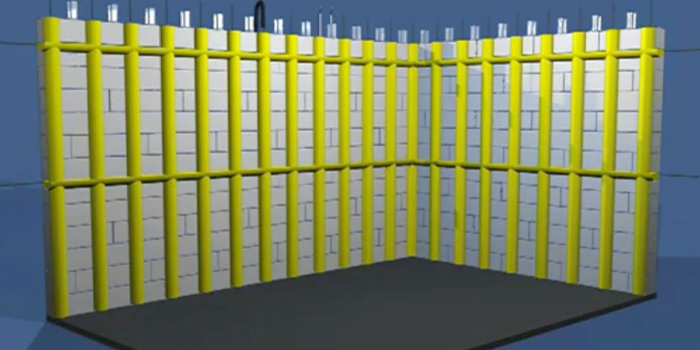

ThermoBlock is a “stay in place” concrete form system used in building construction.

The ThermoBlock system uses a combination of interlocking, stackable polyurethane foam blocks, reinforcing steel rebar, concrete, and steel studs inserted in the wall as straighteners and stabilizers to make a concrete form system. Cells in the wall are then grouted with concrete to form a framework consisting of concrete posts tied together by continuous concrete bond beams spaced as needed.

The foam blocks remain in place after the concrete is poured and readily accept a variety of finishes. Closed cell polyurethane foam has been recognized since the 1950’s as the world’s most efficient insulation material.

The ThermoBlock polyurethane foam blocks are produced by a proprietary injection molding process. The blocks are 8”x 8”x 32”, and have 5 ½” cylindrical openings running vertically through the block, spaced at 8” on centers. The blocks interlock both horizontally and vertically to form a contiguous insulation system with no thermal bridges to allow transfer of heat and cold through the wall systems.