A Conversation with Al Restaino

Spray Foam Magazine: How did Accella come to be such a prominent company in the spray polyurethane foam industry?

Al Restaino: Accella is steeped in polyurethane chemistry history and experience. Since 1973, Accella’s legacy company’s developed and perfected polyurethane binders, coatings, adhesives, elastomers, and foams. Accella quickly grew to be a leader in technology, service, product quality, and reliable supply. It was natural for Accella to look at complementary spaces in technology, chemistry, and raw materials. Our roots in manufacturing and building construction materials also made the move to acquire spray foam manufacturing companies a no brainer. Accella is now part of Carlisle Construction Materials, a leader in building materials science, technology, and operational excellence.

SFM: What steps did Accella take to achieve this status?

AR: Accella purchased three spray foam leaders in the course of two and a half years, starting with Premium Spray Products and the spray foam business units of both Quadrant (QuadFoam) and Covestro (Bayseal). The three businesses have been consolidated into state of the art manufacturing facilities in Cartersville, Georgia and Spring, Texas, providing dual shipping locations and supply continuity to our customer base.

SFM: As VP of Marketing, what goal do you set for yourself and Accella?

AR: Growing the space for polyurethane spray foam insulation is a top priority. The SPF space is growing as a better solution versus alternative technologies (fiberglass insulation) due to the superior insulating air barrier and vapor barrier qualities, which make the building healthier, more comfortable for all of us. We believe the potential for spray foam will be enhanced and grow even faster relative to the value it gives homeowners. Accella is committed to this goal.

SFM: How will you accomplish this goal?

AR: Accella will accomplish this by providing the easiest-to-use products in the industry, providing best-in-class technical support and application service, and communicating the difference in value that spray foam offers to customers versus other alternatives, and outstanding customer service.

SFM: How does Accella provide contractors with the right tools to succeed on the job?

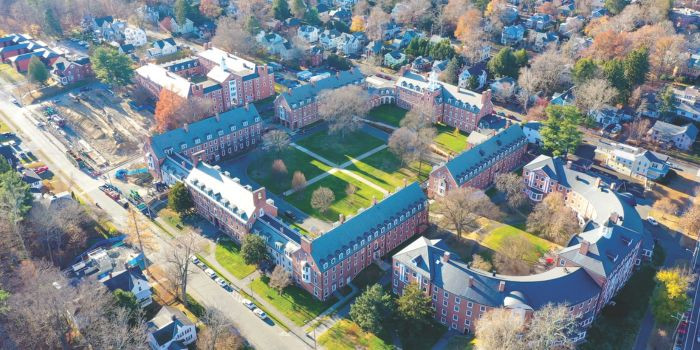

AR: Accella’s commitment to growth includes technical training with its state-of-the-art training facilities located in Las Vegas, Nevada and Carlisle, Pennsylvania. With in-house spray booths and classroom-style rooms, we cover everything from spray foam technology and techniques, safety, new product applications, regulatory and legislative trends, and sessions on lead generation and growth strategy.

Another important area is the value our distributor partners provide. Distribution channels enhance the value to the contractor with right time, right place delivery, as well as managing unique growth trends by geographic markets.

SFM: Are you bringing any new products to market? If so, what can you tell us about them and when can they be expected?

AR: Yes, Accella has multiple products under development. Our product development philosophy is guided by a very simple premise. If they are not easy to use for the spray foam contractor, then why produce it? With that in mind, we now offer multiple high-yield, open-cell spray foams that are easy to spray and require minimal equipment adjustments with significant improvements in yield. As of today, we have experienced a 100-percent conversion rate to this product from other competing products.

SFM: What does the future hold for Accella?

AR: We see continued growth and investment in the SPF category with a focus on creating tools, products, and value for our customers. This includes driving a best in-class technology, new products, training, and earning the position as the number one preferred brand in the SPF industry. •

Disqus website name not provided.