Accella Highlights Optimal Roofing Safety Gear

MARYLAND HEIGHTS, MO – May 1, 2017 – Often spray polyurethane foam job sites require that crews work at elevation. Whether this entails spraying foam onto ceiling joists in a residential attic or applying a new roofing system onto a 24-story building, there are strict rules and regulations that must be followed to ensure worker safety.

The Occupational Safety and Health Administration (OSHA) has established fall protection guidelines for working at heights in Standard 1926.501. “Each employee on a walking/working surface (horizontal or vertical) with an unprotected side or edge which is six feet (1.8m) or more above a lower level shall be protected from falling by guardrail systems, safety net systems, or personal fall arrest systems.” That is an important combination of passive or active protection. The key factor to remember is six feet. If you or your crew will be working at that height – even on a ladder – you must use a method of fall protection in addition to your regular personal protective equipment (PPE).

Know Before You Go

In order to keep your crew safe, SPF contractors must first assess the job site and identify any potential hazards in order to provide the appropriate PPE and safety accommodations. This is in accordance with OSHA’s worker safety requirements found in General Requirements section 29 CFR 1910.132-138. Not only is it the law, it is just common sense. For example, if you are installing a new roof, the perimeter must be marked with flags, lines, or guardrails at a distance of six (6) feet from the edge of the roof. Any skylights must also be clearly identified and marked. These engineered solutions are designed to passively prevent falls.

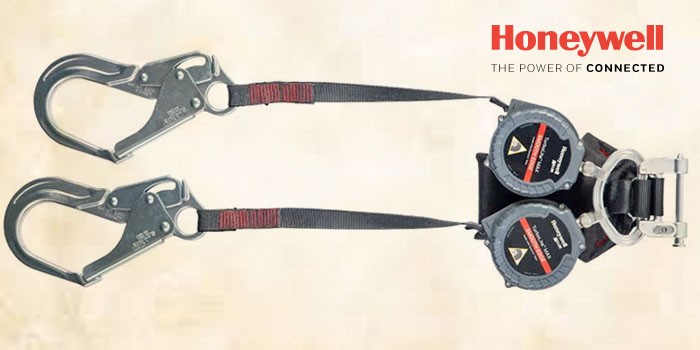

However, if the hazard cannot be addressed through an engineered solution, it must be actively addressed through personal protective equipment (PPE). These types of situations could include working on scaffolding, or in boom lifts – in these cases fall protection, including harnesses with fall-arrest systems could be required. Again, it is the employer’s responsibility to know the hazards before arriving on the site, to address them, and provide proper safety equipment for the crew.

RELATED New Fall Protection Product From Honeywell Reduces Risk of Severed Lifelines for Workers at Height, OSHA Issues Final Rule Updating Walking-Working Surfaces Standards and Establishing Fall Protection Systems Requirements, Tennessee Chill Box Launches Cool-Breeze Chill Suit, OSHA Kicks Off ‘Hear and Now - Noise Safety Challenge’

Correct Usage Saves Lives

In a worst-case scenario, a properly fastened harness with a fall-arrest system will stop a fall. If that harness is too loose; however, the consequences could be dire. The same could be said for a respirator with an improper fit. In the spray foam industry, life and death situations can become commonplace. For this reason, training is absolutely necessary when it comes to PPE. In fact, OSHA’s Standard 29 CFR 1910 states that employers must train employees to recognize hazards, as well as to understand the proper PPE to use and where and when to use it. Further, this training must include the maintenance and disposal of the PPE. After training, employees must state in writing that they have been provided with hazard assessment and PPE training, as well as the proper PPE. Are you in compliance with this OSHA standard? Does your crew have the required gear?

Dressing For (And Addressing) Safety – From The Heights To The Ground

Whether it is a roof or a basement, or something in between, the crew at a typical SPF jobsite should be dressed in variations of the following PPE and/or should have the following equipment on hand:

Respiratory Protection: According to OSHA’s Respiratory Protection Standard 1910.134, contractors must have a written program for respiratory use that is managed by a trained person. The program must outline training, medical evaluations, annual fit tests, and regular maintenance and care procedures. If this sounds like a lot of work, remember, a respirator is the only thing between you and damaged lungs. Contractors can be exposed to dust, lead, and asbestos in the course of a day’s work – not to mention the chemicals, including Iso, that are sprayed. It is vital that your crew is fit tested, up-to-date with training, and passes respiratory protection tests.

Fall Protection: In OSHA’s Safety and Health Regulations for Construction, Standard 1926.501, there is a section entitled “The Duty to Have Fall Protection.” SPF jobsites often include wall openings, elevated areas with unprotected sides, floor holes, scaffolds, and portable ladders – all of which routinely top OSHA’s list as the causes of jobsite injury and death from falls. To address this dangerous situation, OSHA recommends flags and guardrails as a first-line of defense only, and rather recommends the use of harnesses and fall-arrest safety lines, as well as a safety monitor and netting on elevated jobsites.

Eye/Face Protection: The U.S. Bureau of Labor Statistics (BLS) reports that over half of the eye and face injuries suffered by construction workers occur because the workers are not wearing proper PPE. Sadly, the construction industry also has the highest rate of eye and face injuries of all the industries studied, including “Natural Resources / Mining” and “Other”. There is; however, an easy fix – wear goggles or safety glasses with side shields. All safety eyewear should be marked ANSI Z87.1 to show that it complies with the OSHA standard rating. Your sunglasses are not safety gear – although they may shield your eyes from harmful UV rays they will not protect your eyes from flying debris.

Arm/Hand/Body Protection: When spraying SPF all exposed skin must be covered. And just covered isn’t good enough, it must be covered with a chemical-resistant material. Do not use cotton coveralls as the cotton will absorb the chemicals and then transfer them onto – potentially into – your skin. To cover your body and arms, Tyvek or comparable coveralls work well. For your hands, gloves made of leather, nitrile, latex, neoprene, or rubber, can all work, as long as they are constructed of a chemical-resistant material and are rugged enough to withstand the rigors of the job without tearing. If the job entails using blades, then the gloves must also be cut-resistant.

Standard Issue PPE

In addition to the equipment above, there is also a host of “standard issue” PPE – the pieces most contractors and their crew have with them on a daily basis. These wardrobe essentials include steel-toed boots, a hard hat, a reflective vest, and hearing protection.

Whether working in the sun or indoors, another key safety component is hydration. Spraying foam is physically demanding work and it is important to drink lots of water to avoid the risk of heatstroke.

No matter where you are spraying foam – on a roof or on the ground – PPE should be as essential to the job site as your gun and your foam. Dress for success – and safety. After all, the best job is the job where everyone goes home safe at the end of the day.

If you have any questions about a proper PPE program or would like to learn more about safety and spray foam, contact Accella Polyurethane Systems. They have an industry-leading record of safe and successful job site and can help you establish your own successful safety program. •

Contact Accella Polyurethane Systems, LLC

Direct any questions about safety and spray foam to Accella Polyurethane Systems, LLC:

Phone: 770-607-0755

Website: www.accellapolyurethane.com

Photos Courtesy of Accella Polyurethane Systems, LLC

*Spray Foam Magazine does not take editorial positions on particular issues; individual contributions to the magazine express the opinions of discrete authors unless explicitly labeled or otherwise stated. The inclusion of a particular piece in the magazine does not mean that individual staff members or editors concur with the editorial positions represented therein.

Disqus website name not provided.