Do Polyurea Spray Systems Cure in Seconds?

SPRAY FOAM MAGAZINE – It is well known that polyurea spray elastomer systems are reported as having very fast cure times. We see it in all the marketing info, training sessions, etc. Notations even point to curing within seconds, and some have even been so bold as to note a “Snap Cure” with these systems…WHAT??? To most folks out there, “snap” means instant/right now, like the snap of your fingers, but is this the true case with polyurea spray systems?

Most systems are noted as having gel and tack-free times, typically within a few seconds to short minutes, hence the processing requirement using plural component, high-pressure, high-temperature impingement mix spray processing. Try mixing those two parts by hand and producing a quality product.

This gel time is the time at which the mixed materials go from a liquid, flowable state, to a “solid.” This is akin to reported “pot life” or working time for conventional coating materials. In lay terms, this means the time at which the material is usable in installation work. In other words when the mixed viscosity exceeds the viscosity at which it can be properly applied. But that fast gel time, or pot life, is NOT cure time! Gel time and tack-free evaluation testing is used in the field by the applicator to confirm that the material is being processed properly.

Physical Property Testing

From an applicator perspective, a specific product Technical Data Sheet (TDS) is a valuable piece of information. One should have this handy at all times when on a project, and most importantly reviewing that BEFORE the project starts. The noted physical properties, such as Tensile Strength and Elongation (ASTM D 412, Die C or ASTM D 638, Type IV), Tear Strength (ASTM D 634, Die C) and Durometer Hardness (ASTM D 2240, Shore A or D) for example are reported on prepared, cured material samples.

From the physical applicator standpoint, the important information relates to gel time and tack-free time. This will give one an indication that processing parameters are being met, and the proper material is being produced. Measuring Shore Hardness within about one to two hours after application, can also help confirm the systems have been applied on-ratio and on-mix. But understand, one required a minimum of 60 mils (1.5 mm) to properly run this field test.

GEO-TEAR STRESS:Examples of material cracking / tearing from moving into place before reaching its cure point

But since these physical property tests are run as per standardized test methods, such as the noted ASTM, or ISO, EN, DIN etc., one may overlook the actual requirements of the testing procedure. Importantly enough (and from ASTM methods noted) samples are to be conditioned under controlled environmental exposure before testing. And this would be conditioning the prepared samples at 23 ± 2 °C (73.4 ± 3.6 °F) and 50 ± 5% humidity for a minimum of 40 hours before testing. The AMPP SSPC-Paint 45 coating performance standard on Polyurea and Polyurea/Polyurethane Hybrids actually notes a minimum of five days conditioning before testing.

This also relates to spray foam application as many are performing the density tests in the field as inspection or confirmation of application. Regardless of whether one is using the proper ASTM D 1622/1622M (cellular plastics) or ASTM D 792 (water displacement, non-cellular plastics), the prepared foam sample is to be conditioned before testing. These tests also require conditioning at a minimum of 40 hours at 23 ± 2 °C (73.4 ± 3.6 °F) and 50 ± 10% humidity. What one is noting is an indication of density met, but not the true density as the spray foam samples had not been conditioned properly nor has the foam reached cure yet.

Field Implications

Numerous videos are available online that show a polyurea spray system being applied to a concrete Haydite block wall, or even coating a watermelon. A sledgehammer is used to beat on the polyurea surface of the constructed wall, showing breakage of the block wall and no damage to the polyurea. Well, what is not shown is that this testing is not immediate, but after a period of time to allow for some strength build, often referred to as “green strength” development. Remember spraying test samples on a release plaque, the material tears easily at first. But after about an hour for most systems, green strength has developed, but not fully cured.

While on a major polyurea spray project over 20 years ago, the Boston MBTA tunnel waterproofing project, the contractor had started the application of the polyurea spray elastomer system. The concrete had been prepared properly, and the proper epoxy primer used, and retain samples were sprayed that morning. Later that morning, an inspector showed up and shut the project down. Why you may ask? Well, he had taken one of the retain samples to a local respected test lab and the tested properties of the sample were not even close to that reported on the TDS and specification requirements. This would indicate that there was a problem with the application and/or material.

When inquired of the inspector as to what test methods were used, he of course spouted off the typical ASTM methods (as noted previously) that had been employed. I then reminded him that NO they did not test as to those standards! If they ran those specific procedures, then there was no time for the samples to undergo the required conditioning state and time as per the ASTM Methods. Meaning the samples had not reached cure state, yes, they were set / hard, but… When they re-ran the samples two days later, all was in-line with the product TDS and specification requirements.

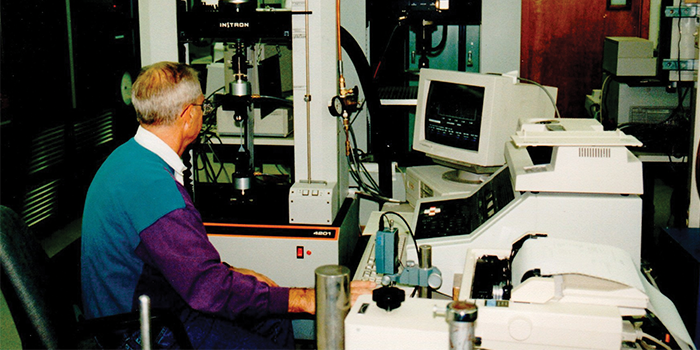

One major polyurea contractor, who is primarily involved in the use of polyurea coating and lining systems in quality nuclear application work, actually has a small QC lab inside each trailer rig. After they spray a retain sample, they place that sample in a convection oven and heat to 250 °F (120 °C) for one hour. They then test the “post cured” sample for properties, documenting that they have processed the material properly and met the physical property requirements noted on the product TDS. This annealing process has been a common practice with polyurea based systems, especially in the polyurea automotive RIM application area.

So what happens if too much stress, or abuse, is applied to a polyurea spray system before it has actually reached a certain cure state? The following two pictures are a polyurea geotextile system applied to geotextile fabric as in pre-sprayed use and installation. Shortly after spraying, the coated panel was then pulled and moved into place. As a result, tearing of the applied polyurea occurred as the material had not yet reached a cure point. While the applied polyurea has set, and was dry, the green strength developed had not occurred yet. This has been noted numerous times in pre-sprayed panel work and field spray installation, and some have indicated that there must have been a spray processing issue.

Conclusion

An interesting point to ponder here. While polyurea spray systems are noted as having a fast cure time, the cure is not instant, but takes time. With that noted, each type of polyurea system can exhibit various final cure times, some slower, some faster, but cure time is the period of time when a polyurea material attains its ultimate physical properties. Use caution here as many systems may reach a “cure point” within a short period of time that would allow use in a particular application but have NOT reached ultimate physical properties. The cure time varies on different formulations, with the high hardness, low elongation systems reaching full cure faster than the slower, higher elongation systems. This ultimate “cure” may be 24 to 48 hours plus after application.

Disqus website name not provided.