Graduating to Efficiency

SPRAY FOAM MAGAZINE – What happens when the initial insulation specified is unable to fill a gap due to the area’s limited access? An inadequate insulation installation can end up with unwanted air leaking into the building resulting in wasted energy and a reduction of the overall R-value performance of the building. It can also cause moisture buildup, mold, and even infestations of bugs or mice. Spray Foam Magazine heard of such a dilemma and spoke with some experts who accessed the situation. Were they able to find a solution to make everyone from the design team to the construction manager happy? We headed to Maryland to find out.

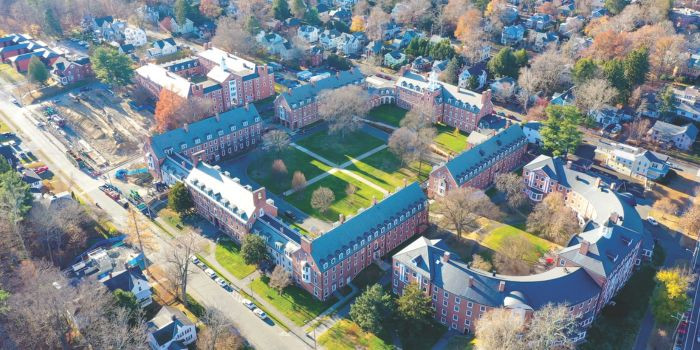

Located in a residential section of Baltimore, Maryland, Morgan State University covers an area of just over 143 acres. It has become the principal public urban research university in the state, with a reputation for excellence in teaching, intensive research, effective public service, and community engagement. It also has a new 208,000-sq.-ft. Health and Human Services Building. This impressive facility includes a state-of-the-art classroom, lab, demonstration office, in addition to community spaces for the School of Community Health and Policy. It is slated to open towards the end of 2024.

The new building is designed by HOK, a renowned global design, architecture, engineering, and planning firm. HOK has a reputation as being forward-thinking and dedicated to improving people’s lives and healing the planet by using sustainable materials, creating healthy spaces, and purpose-driven designs. The construction manager for the project is Barton Malow and JLN, who also have an outstanding reputation for integrity, innovation, and trust.

Wiss, Janney, Elstner Associates, Inc (WJE), a firm of engineers, architects, and material scientists, has been involved with this project since the building’s early design. Julie Szabo is the Associate Principal at WJE, and her area of practice is Building Science/Enclosure Consultant. She is also a project manager on this build.

“Our contract is held by Barton Malow on behalf of Morgan State. WJE has been serving in this role for Barton Malow and Morgan at the University for approximately 10 years with many completed projects and additional projects upcoming,” confirmed Szabo. Jack Nuttmann of WJE is the project associate on this build and had a regular field presence including overseeing the initial foam application process.

The six-story building includes a concrete frame and an exterior wall enclosure with a combination of precast concrete panels and an aluminum-framed curtain wall. There are vegetative green roof assemblies at multiple levels and terrace spaces for students. The vegetative roofs are increasingly popular in sustainable designs because the vegetation helps soak up the rainwater into the plants and lessens the chance of overflow. A vegetated roof can also help decrease the results of the heat island effect through the process of evapotranspiration. This helps urbanized areas that experience high temperatures with building and infrastructure absorb and re-emit the sun’s heat. The vegetation also adds additional insulation to a building, helping reduce the amount of energy needed to control the temperature.

The exterior wall design includes mineral wool insulation continuously installed on the interior side of the precast concrete panel. A smart vapor retarder is provided on the interior side of the insulation and is installed continuously to prevent interior air/vapor from reaching the interior face of the precast concrete panel where it can condense in colder weather. At the north side of the building, near the main entrance, a 12-in.-thick concrete shear wall is located on the interior side of the precast concrete exterior wall panel for an approximately 25-ft. area on all four floors of this portion of the building.

The gap between the shear wall and the precast concrete panels varies from six to 12 in., which did not allow the installation of mineral wool and smart vapor retarder because of limited access for the installation. The team therefore had to think of an alternative. WJE proposed the use of closed-cell spray foam insulation to be applied between the concrete shear wall and precast concrete exterior wall panel in this area.

The limited access also created concerns with access to apply the spray foam continuously within this gap and not being able to leave any air spaces or gaps where convective looping may occur.

WJE’s Julie Szabo has a lot of experience with SPF, specifically closed-cell medium-density foam since the WJE team has used it in several applications. It has previously been used to provide a continuous air barrier in addition to thermal control, especially on the interior side of the precast concrete or mass masonry walls where the interior surface of the wall will be cold in colder weather. However, she suspected that closed-cell may not work for this application.

Szabo went to university with Rocky Boyer, who is the Building Science and Sustainability Manager at Elastochem. “Once we saw that the contractor proposed an Elastochem product, I reached out to Rocky to learn more about Pour 220 and if it would be a good fit for the project. Rocky told me that the formulation of the Pour 220 could be adjusted as necessary to best fill the gap. He also stated that an on-site mockup of the foam was required to determine if any parameters, including formulation, application temperature, spray trigger time, etc., should be modified to best fit the project-specific conditions.” explained Szabo.

Scott Cameron has been in the spray foam industry since 2008, and he is the owner of Cameron Building Envelope Specialists, LLC located in Elkridge, MD.

With expertise in SPF, air/vapor barriers, thermal barriers, and building science, they bring knowledge and innovation to every project they work on, including this one. Cameron got involved when he heard the general contractor was searching for solutions to insulate a blind cavity.

“We originally submitted the Elatochem Pour 220 and presented it to the design team. WJE reviewed the submittal and approved the product after they spoke with Elatochem’s technical team. We have tried the product before on prefabricated wall assemblies and had previous success with it. We knew it would be the right foam for this application,” confirmed Cameron.

The Cameron Building Envelope Specialists arrived on-site with a crew of two, which included their lead applicator Enrique Martinez, a 15-year veteran sprayer. They used a Graco E30i, Accurate Dynamics hoses, and a Graco Fusion AP gun with cannon tip and wore their standard PPE for interior spray foam which included Tyvek suits, cut-resistant gloves, and a fresh air respirator.

Due to space constraints, the Cameron crew utilized a cannon tip to apply the foam in a steady stream of between eight and 12 ft. This tip allowed the foam to be carried a longer distance than a traditional tip used for most foam applications. The gap was approximately 25 ft. in length, so it was determined that the application of the foam from both sides of the gap was required.

The foam was applied in approximately six-in.-tall lifts as recommended by Elastochem and the application temperature was increased from 112°F to 120°F to speed up cure time after several mockup lifts were applied.

The surface temperature of each lift was monitored using a temperature gun before applying the next lift. Drywall and other construction materials were then used to confine the foam to the gap. The crew installed the foam at a speed of one floor per day. “These types of projects can be tricky. However, this one went smoothly as we have an experienced lead sprayer and had great help from Elastochem’s technical team. The client couldn't be happier with the speed of application and quality installation,” states Cameron.

By combining the ingenuity of Elastochem’s technical team, the talents of The Cameron Building Envelope Specialists, and the WJE team’s enclosure expertise, a blind cavity was insulated to a high standard and any potential issue was avoided. “We were very happy with the results and are interested in using Pour 220 again in areas where traditional closed-cell SPF cannot be installed due to the cure time,” concluded Szabo.

What happens when the initial insulation specified is unable to fill a gap due to the area’s limited access? An inadequate insulation installation can end up with unwanted air leaking into the building resulting in wasted energy and a reduction of the overall R-value performance of the building. It can also cause moisture buildup, mold, and even infestations of bugs or mice. Spray Foam Magazine heard of such a dilemma and spoke with some experts who accessed the situation. Were they able to find a solution to make everyone from the design team to the construction manager happy? We headed to Maryland to find out.

Located in a residential section of Baltimore, Maryland, Morgan State University covers an area of just over 143 acres. It has become the principal public urban research university in the state, with a reputation for excellence in teaching, intensive research, effective public service, and community engagement. It also has a new 208,000-sq.-ft. Health and Human Services Building. This impressive facility includes a state-of-the-art classroom, lab, demonstration office, in addition to community spaces for the School of Community Health and Policy. It is slated to open towards the end of 2024.

The new building is designed by HOK, a renowned global design, architecture, engineering, and planning firm. HOK has a reputation as being forward-thinking and dedicated to improving people’s lives and healing the planet by using sustainable materials, creating healthy spaces, and purpose-driven designs. The construction manager for the project is Barton Malow and JLN, who also have an outstanding reputation for integrity, innovation, and trust.

Wiss, Janney, Elstner Associates, Inc (WJE), a firm of engineers, architects, and material scientists, has been involved with this project since the building’s early design. Julie Szabo is the Associate Principal at WJE, and her area of practice is Building Science/Enclosure Consultant. She is also a project manager on this build.

“Our contract is held by Barton Malow on behalf of Morgan State. WJE has been serving in this role for Barton Malow and Morgan at the University for approximately 10 years with many completed projects and additional projects upcoming,” confirmed Szabo. Jack Nuttmann of WJE is the project associate on this build and had a regular field presence including overseeing the initial foam application process.

The six-story building includes a concrete frame and an exterior wall enclosure with a combination of precast concrete panels and an aluminum-framed curtain wall. There are vegetative green roof assemblies at multiple levels and terrace spaces for students. The vegetative roofs are increasingly popular in sustainable designs because the vegetation helps soak up the rainwater into the plants and lessens the chance of overflow. A vegetated roof can also help decrease the results of the heat island effect through the process of evapotranspiration. This helps urbanized areas that experience high temperatures with building and infrastructure absorb and re-emit the sun’s heat. The vegetation also adds additional insulation to a building, helping reduce the amount of energy needed to control the temperature.

The exterior wall design includes mineral wool insulation continuously installed on the interior side of the precast concrete panel. A smart vapor retarder is provided on the interior side of the insulation and is installed continuously to prevent interior air/vapor from reaching the interior face of the precast concrete panel where it can condense in colder weather. At the north side of the building, near the main entrance, a 12-in.-thick concrete shear wall is located on the interior side of the precast concrete exterior wall panel for an approximately 25-ft. area on all four floors of this portion of the building.

The gap between the shear wall and the precast concrete panels varies from six to 12 in., which did not allow the installation of mineral wool and smart vapor retarder because of limited access for the installation. The team therefore had to think of an alternative. WJE proposed the use of closed-cell spray foam insulation to be applied between the concrete shear wall and precast concrete exterior wall panel in this area.

The limited access also created concerns with access to apply the spray foam continuously within this gap and not being able to leave any air spaces or gaps where convective looping may occur.

WJE’s Julie Szabo has a lot of experience with SPF, specifically closed-cell medium-density foam since the WJE team has used it in several applications. It has previously been used to provide a continuous air barrier in addition to thermal control, especially on the interior side of the precast concrete or mass masonry walls where the interior surface of the wall will be cold in colder weather. However, she suspected that closed-cell may not work for this application.

Szabo went to university with Rocky Boyer, who is the Building Science and Sustainability Manager at Elastochem. “Once we saw that the contractor proposed an Elastochem product, I reached out to Rocky to learn more about Pour 220 and if it would be a good fit for the project. Rocky told me that the formulation of the Pour 220 could be adjusted as necessary to best fill the gap. He also stated that an on-site mockup of the foam was required to determine if any parameters, including formulation, application temperature, spray trigger time, etc., should be modified to best fit the project-specific conditions.” explained Szabo.

Scott Cameron has been in the spray foam industry since 2008, and he is the owner of Cameron Building Envelope Specialists, LLC located in Elkridge, MD. With expertise in SPF, air/vapor barriers, thermal barriers, and building science, they bring knowledge and innovation to every project they work on, including this one. Cameron got involved when he heard the general contractor was searching for solutions to insulate a blind cavity.

“We originally submitted the Elatochem Pour 220 and presented it to the design team. WJE reviewed the submittal and approved the product after they spoke with Elatochem’s technical team. We have tried the product before on prefabricated wall assemblies and had previous success with it. We knew it would be the right foam for this application,” confirmed Cameron.

The Cameron Building Envelope Specialists arrived on-site with a crew of two, which included their lead applicator Enrique Martinez, a 15-year veteran sprayer. They used a Graco E30i, Accurate Dynamics hoses, and a Graco Fusion AP gun with cannon tip and wore their standard PPE for interior spray foam which included Tyvek suits, cut-resistant gloves, and a fresh air respirator.

Due to space constraints, the Cameron crew utilized a cannon tip to apply the foam in a steady stream of between eight and 12 ft. This tip allowed the foam to be carried a longer distance than a traditional tip used for most foam applications. The gap was approximately 25 ft. in length, so it was determined that the application of the foam from both sides of the gap was required.

The foam was applied in approximately six-in.-tall lifts as recommended by Elastochem and the application temperature was increased from 112°F to 120°F to speed up cure time after several mockup lifts were applied.

The surface temperature of each lift was monitored using a temperature gun before applying the next lift. Drywall and other construction materials were then used to confine the foam to the gap. The crew installed the foam at a speed of one floor per day. “These types of projects can be tricky. However, this one went smoothly as we have an experienced lead sprayer and had great help from Elastochem’s technical team. The client couldn't be happier with the speed of application and quality installation,” states Cameron.

By combining the ingenuity of Elastochem’s technical team, the talents of The Cameron Building Envelope Specialists, and the WJE team’s enclosure expertise, a blind cavity was insulated to a high standard and any potential issue was avoided. “We were very happy with the results and are interested in using Pour 220 again in areas where traditional closed-cell SPF cannot be installed due to the cure time,” concluded Szabo.

For use by SprayFoamMagazine.com & Spray Foam Magazine

Disqus website name not provided.