Huntsman Building Solutions hosts Lunch and Learn for Architecture Firm in South Florida

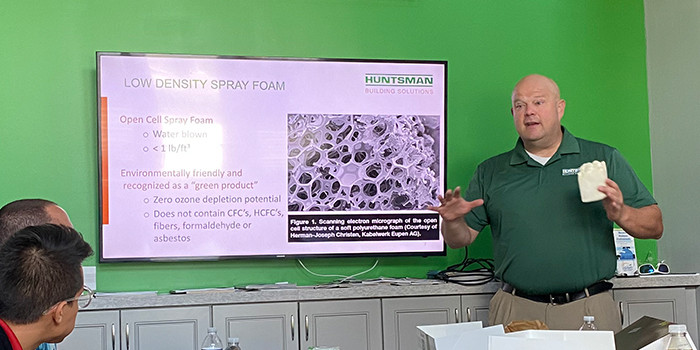

PALM BEACH, FL – October 12, 2021 – Grant Ostvig is the Director of Commercial Development at Huntsman Building Solutions. One of Ostvig’s many jobs is to teach people about the benefits of spray foam, so he was looking forward to speaking with the architects at Steve Siebert Architecture (SSA), located in the Palm Beach area in South Florida.

The SprayFoam.com team caught up with Ostvig before his lunch at Siebert’s and asked him why the American Institute of Architects (AIA) lunch and learns were relevant. “Huntsman Building Solutions has been providing Architectural continuing education for decades now. In the beginning we had to explain what spray foam was, and we had to prove code justification to allow foam to replace traditional materials. Today’s architects have grown up watching home improvement shows and they know that foam is the superior product. Therefore, conversations with architects today now focus more on the cost savings benefits of foam in exterior continuous insulation and the many unique applications. These productive Lunch and Learns result in a partnership between architects and manufacturers. By being a good steward for the foam industry, widespread architectural acceptance becomes much easier,” said Ostvig.

Steve Siebert Architecture is a design team of architects, planners, interior designers, and engineers who work on both residential and commercial projects. The team at SSA provide a custom service to the entire state of Florida, and their designs range from historic traditional to modern contemporary, also including interior remodel and additions.

Sprayfoam.com spoke with the principal architect, Steve Seibert, to see how this lunch and learn session went.

SF: Did your team find the lunch and learn productive?

SS: It went well. We’ve been struggling to learn whether to use closed-cell versus open-cell. For example, what’s the proper way to seal up an attic. We are based in South Florida where we have a lot of humidity and mold can be a real issue. Grant was very helpful explaining the differences between the foams and in addition suggested talking with our engineer about adding some positive pressure in the attic with the HVAC system with supply air to push that air back into the home and keep it circulated.

Steve Siebert (left) and Grant Ostvig (right)

SF: Did anyone else from Huntsman attend?

SS: Yes. Chad Butler who is Huntsman’s Territory Manager based in Jacksonville. Chad will be our primary contact here in Florida. The Huntsman team made it clear that if we had a specific question, we should contact Chad and he would get a hold of his experts to get a reasonable solution or suggestion back to us.

SF: Have you an interesting project in the works where spray foam will be applied?

SS: The day after the lunch and learn, I was in Jacksonville to support a few projects up there. One of them is a multipurpose building that was slated by a previous company to be pre-engineered metal steel. In the meeting, I convinced the client to switch to a pole barn. It’s a cheaper building but the pre-engineered metal companies are struggling with steel production and steel fabrication. We were looking at a ten-month delay for the structural super shell, but we could order a pole barn and have it on site to erect in a month. The outside looks the same and we can also put the same metal that was on the original design. I suggested for stability and insulation purposes, rather than using scrim (a woven material used to reinforce a building), we could spray foam right on the back of the steel. Then we can seal it all in with the dry wall and plywood and anything else we may need. The client said yes. They were especially happy when I suggested there would be a financial savings to that package. The spray foam may be more expensive than the scrim, but the benefits are greater.

After the lunch and learn Ostvig summarized the event, “With Steve Seibert Architects work being in Florida many of their questions centered around indoor moisture management and how spray foam and HVAC equipment must work together to establish a balanced system. The Lunch and Learn that was presented was titled Spray Foam in Commercial Design. During this presentation we briefly mentioned 3-pound roofing foam. It was apparent that Steve Seibert Architects was unaware that SPF Roofing achieves Florida NOA, (Notice of Assignment). At the end of the AIA Lunch and Learn Steve Seibert requested a second one that Huntsman offers that specifically addresses Spray Foam Roofing. We look forward to our next AIA Lunch and Learn with Steve Seibert Architects.”

Most Architects join The American Institute of Architects (AIA) as a form of professional accreditation. As part of the organization, they are required to participate in 18 hours of continuing education so that they are up to date with trends and changes in the construction and construction products industry. The presentation provided by Huntsman Building Solutions is a 1 hour class delivered to the architects over their lunch hour. The class counts as 1 hour of credit. When the class is over, Ostvig sends a form to the AIA organization with every architect’s AIA number who attended and they get credit for and a certificate of completion that counts towards their annual continuing education hours.

If you are interested in an AIA Lunch and Learn, please contact margo@sprayfoam.com for details.

Disqus website name not provided.