New Spray Foam Rig Boasts Increased Efficiencies in Material Heating and Spraying

Pella, Iowa, September 2009 – Not all spray foam rigs are created equal. DiiMON SI has taken an underutilized technology to a new level with the creation of their 602 series plural component spray rigs. With outside the box thinking that accompanies all of DiiMON SI’s parent company’s products, they have taken mobile spray foam and coating rigs and raised the bar. DiiMON SI has developed a system that captures the energy and the heat from the Power Unit to deliver unparalleled spray performance in the most varied climates.

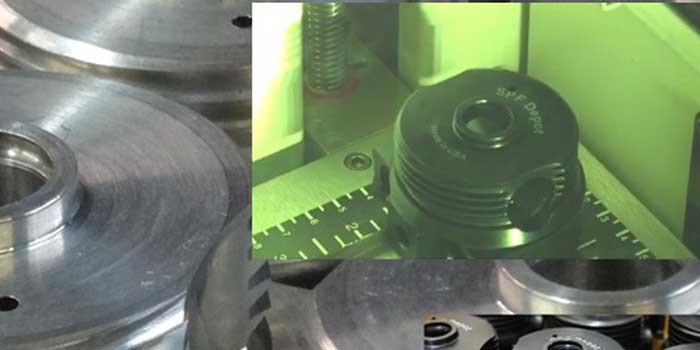

DiiMON SI 602 series mobile spray rigs follow similar spray rig designs in that they utilize either trailer or truck box footprints. While the outside may look the same, the inside is a whole different story. DiiMON 602 series spray rigs are driven by an engineered Power unit comprised of a Tier III high performance diesel engine with a direct drive high efficient rotary screw compressor. The air is used to power the fluid handling components and the heat is recovered to provide this rig with a ?T of over 100°… while spraying with 2 guns. In many cases, there is no need to preheat your material before spraying. Couple that with DiiMON SI’s Auto-Balance™ system that keeps your material on ratio without having to manually bleed the pressure off of a line, and you have the most user-friendly spray rig on the market.

The Innovations don’t stop there. From the standard touch screen display that monitors all the rig’s systems to the design of the heated hose assembly, DiiMON SI has developed over 19 innovations to make the life of the spray foam contractor easier and more profitable. As an example of innovations available now; there is the Power Unit which is computer controlled to operate as efficiently as possible by varying the engine speed based upon the amount of air and heat needed to maintain your spraying patterns. This has resulted in a savings of fuel by as much as 50% over other spray rigs on the market not to mention the reduced wear and tear on the mechanical components. For innovations coming soon; there is the hydraulically or pneumatically powered hose reel to wind up the 300’ of hose at the end of a long day of spraying. Although this innovation has been attempted in the past, DiiMON SI’s revolutionary hose design works with this reel system without having to worry about failed electrical connections or worn out hose and insulation assemblies.

View the all the innovations that are available or in the works on their website at www.diimonsi.com. DiiMON SI 602 series spray rigs are available now from their state of the art manufacturing facility in Pella, IA. DiiMON SI offers full training and support on any of the equipment they sell.

About DiiMON Spray Innovations:

DiiMON SI is a wholly owned subsidiary of LDJ Manufacturing in Pella, IA. In business since 1995, LDJ has built its reputation on using sound engineering principals and only the highest quality of materials in anything manufactured at their state of the art facility. They are a company that understands what it means to manufacture a high quality product and stand behind it with strong customer service and support as is evidenced by the many products that have been in process for years. Please visit the LDJ website for a list of products manufactured and supported at www.ldj-products.com.

For more information regarding DiiMON SI, please visit their website at www.diimonsi.com.

Contact:

Donald Mark Tiskevics, Director

Phone: 877-662-7288

Email: don@diimonsi.com

Disqus website name not provided.