Touch ‘n Seal Reveals How to Find the Right Kit for a Spray Polyurethane Foam Insulation Project

FENTON, MO – November 16, 2015 – It is no secret that using low-pressure foam systems such as Touch ‘n Seal’s foam kits during small and medium-scale spray foam applications can be easier and less expensive than high-pressure systems. Using these self-contained, portable, and disposable systems cuts out the time-consuming periods of high-pressure equipment setup and site cleanup seen in large jobs while still providing a quality foam installation. Whether the job calls for applying closed-cell spray foam to a room addition, an attic, a basement, a crawlspace, or to the rim joists of a home, the application of low-pressure foam results in the air sealing and insulating of each area, adding to the weatherization of the whole structure. But before any of that takes places, the spray foam applicator needs to assess the size of the system needed for the job.

According to Touch n’ Seal’s Jonathan Fore, one of the main considerations when determining the right SPF kit to use is appraising the number of board feet that the spray foam application consists of.

“Whether foaming rim joists or stud pockets, calculating the total number of board feet needed is essential to determine which kind of spray foam kit to get,” said Fore.

Touch ‘n Seal offers a complete product line of two-component kits that suit these types of applications based on board feet. These foam kits include closed-cell spray foam that is applied at a two-inch thickness. Among these kits is the FK-15, which is designed to cover about a three-by-four-foot area and is perfect for sealing around outlet boxes and ductwork seams. Then, there is the FK-200, which allows the applicator to cover 200 board feet and it is commonly utilized for rim joist and knee wall applications. Next, you have the FK-600, which is used in structures that encompass 600 board feet such as basements, small room additions, and crawlspaces. Additionally, Touch ‘n Seal offers their CP-750 kit, which is compatible with their portable Constant Pressure Dispensing System (CPDS) Spray Foam Machine. Since the CP-750 allows for 750 board feet of foam application, this kit is often used by contractors to do multiple small jobs.

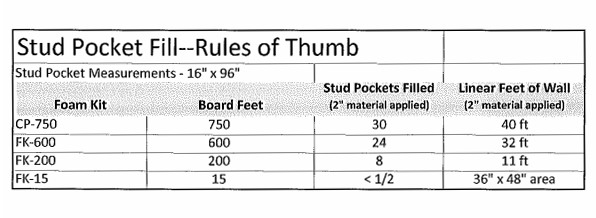

If the job entails filling wall studs with spray polyurethane foam, applicators are inclined to translate the board feet of space that will be foamed into how many stud pockets the low-pressure foam will be able to fill. It goes without saying that a Touch ’n Seal foam kit’s capacity to fill stud pockets varies with each product, but it certainly helps to know some “rules of thumb” prior to the application (see image below).

“You obviously wouldn’t use an FK-15 if you have 30 stud pockets to fill,” said Fore. “But calculating beyond that can be tricky, which is why knowing a couple calculation shortcuts can save you time and cut down on waste at the end of the job.”

Touch ‘n Seal will exhibit their two-component kits and other products at the upcoming Sprayfoam Convention & Trade Show in Orlando, Florida.

About Touch n’ Seal: Convenience Products, the manufacturer of Touch ‘n Seal products, is headquartered in Fenton, Missouri. Touch ‘n Seal insulating foams and sealants are the benchmark for performance in residential, commercial, and industrial building and maintenance, OEM manufacturing and specialty applications. For more information on Touch n' Seal, please use the contact information and links provided below.

RELATED Increase Material Yield With New Low-Pressure System, New Home Sales Surge Provide Momentum to Spray Foam Industry , Dodge Momentum Index Jumps in September

Disqus website name not provided.